The chemical composition of MN13 steel is shown in the following table:

| Element | Content Range |

| Manganese (Mn) | 12.0% – 14.0% |

| Carbon (C) | 1.0% – 1.4% |

| Silicon (Si) | 0.3% – 0.8% |

| Phosphorus (P) | ≤ 0.04% |

| Sulfur (S) | ≤ 0.04% |

| Iron (Fe) | Balance |

The applications of MN13 steel are as follows:

- Mining Industry:

- Crusher liners are used to protect the crusher from wear caused by ores, extending the service life of the crusher.

- Excavator buckets, due to their excellent abrasion resistance, can withstand the wear and tear of rocks and soils during excavation work.

- Ball mill liners play an important role in the grinding process of ores, ensuring the efficient operation of the ball mill.

- Conveyor chutes can resist the abrasion of ores during transportation, reducing equipment maintenance costs.

- Construction Industry:

- Bulldozer blades can maintain sharpness and wear resistance during earthmoving work, improving work efficiency.

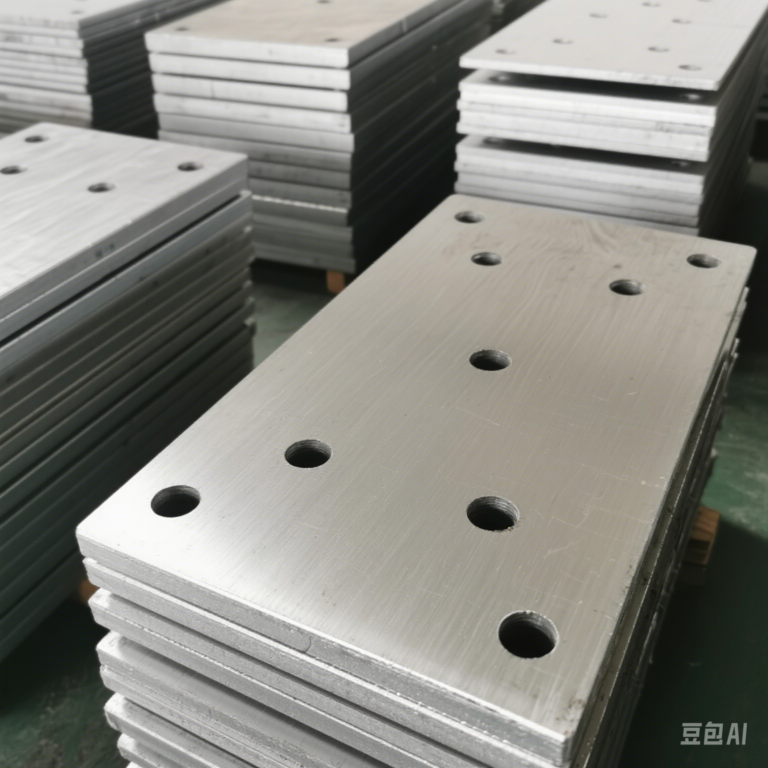

- Wear plates are used in various construction machinery to resist wear and prolong the service life of components.

- Dump truck liners can protect the truck body from the abrasion of materials being transported.

- Excavator teeth can maintain good cutting performance and durability in the process of excavation.