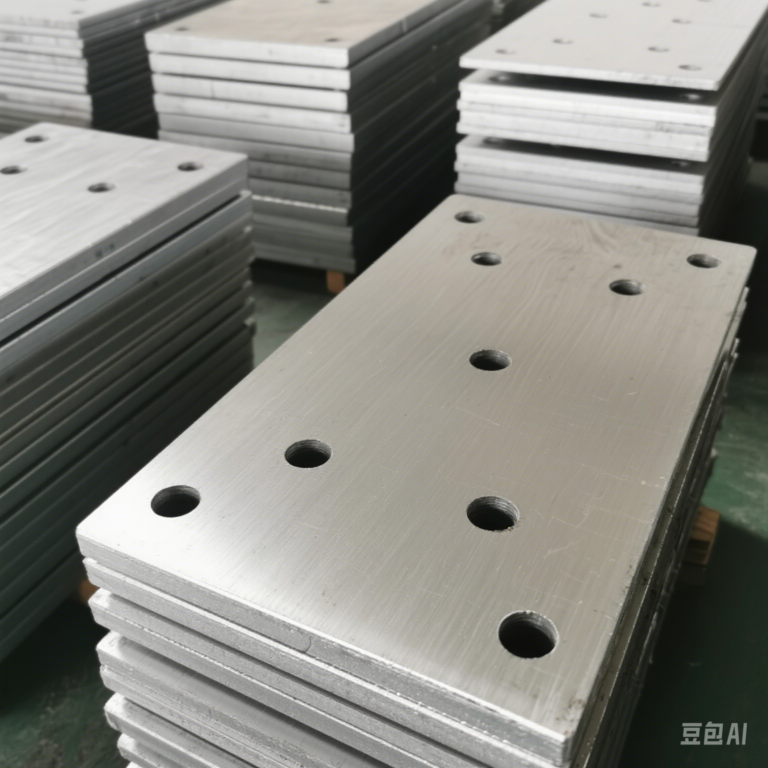

Introduction to Electromagnetic Control Permanent Magnet Chuck

The electromagnetic control permanent magnet chuck is an adsorption device made based on the principle of electromagnetic control of permanent magnetic force. Inside the chuck, there are permanent magnet blocks that can generate a relatively strong magnetic force without power supply. By controlling the on and off of the current, the magnitude of the adsorption force can be changed to achieve the adsorption and release of metal objects. The advantages of the electromagnetic control permanent magnet chuck include adjustable adsorption force, low energy consumption, and high stability.

One-Time Operation for Magnetization and Demagnetization

- The electro-permanent magnet chuck only uses electrical energy during the magnetization and demagnetization stages.

- No power supply is required during the processing.

- Demagnetization is thorough and will not cause magnetization effects on the work-piece.

Power Saving and Energy Conservation, No Thermal Deformation

- No electricity is needed during the processing, saving a large amount of electrical energy.

- There is no thermal deformation, effectively ensuring the processing accuracy.

- It avoids losses caused by sudden power outages and disconnections in the electromagnetic system.

Uniform Magnetic Force, High Processing Precision

- The magnetic force is strong and uniform, resulting in high processing precision.

- The suction force on the tabletop is 13 – 23 kg/cm², and it can effectively adsorb various magnetic conductive steels.

- Quality assurance, capable of handling high loads.

Waterproof and Oil-Resistant

- It is not afraid of splashes of oily or water-based liquids such as cutting oil.

- It is connected with waterproof and oil-resistant connectors for easy plugging and unplugging.

| Dimensions(mm) | |||

| L | W | H | |

| 300*800 | 800 | 300 | 63 |

| 300*1000 | 1000 | 300 | 63 |

| 400*800 | 800 | 400 | 63 |

| 400*1000 | 1000 | 400 | 63 |

| 600*1000 | 1000 | 600 | 63 |

| 600*1500 | 1500 | 600 | 63 |

| 800*1000 | 1000 | 800 | 63 |

| 800*1500 | 1500 | 800 | 63 |

| 800*1600 | 1600 | 800 | 63 |

| 1000*1000 | 1000 | 1000 | 63 |

| 1000*2000 | 2000 | 1000 | 63 |

| 1200*2000 | 2000 | 1200 | 63 |