1.2379 Steel

Standards

| Mat. No. | DIN | EN | AISI/SAE |

| 1.2379 | X155CrVMo12-1 † | X153CrMoV12 | D2 |

Typical Chemical Composition (in weight %)

| C | Si | Mn | Cr | Mo | Ni | V | W | Others |

| 1.53 | 0.35 | 0.40 | 12.00 | 0.8 | – | 0.95 | – | – |

Description

This alloy is one of the cold work, high carbon, high chromium type tool steels. D2 is a deep hardening, highly wear resistant alloy. It hardens upon air cooling so as to have minimum distortion after heat treatment.

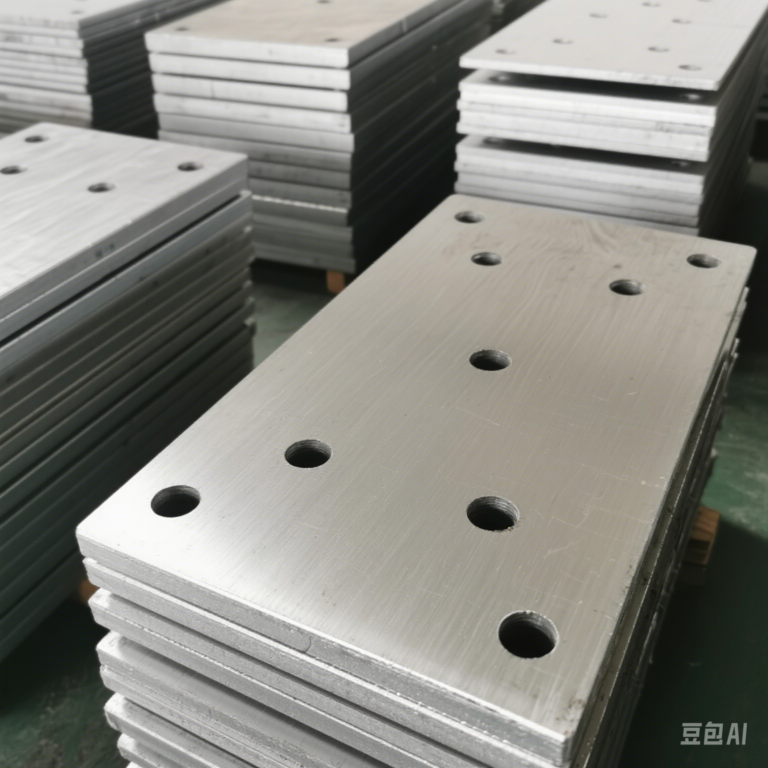

Applications

Used for long run tooling applications where wear resistance is important, such as blanking or forming dies and thread rolling dies, cutting tools, stamping, woodworking, moulding tools for plastics. Toughness better than in D3. Possibility of nitriding.

Physical properties (average values) at ambient temperature

Modulus of elasticity [103 x N/mm2]: 210 Density [g/cm3]: 7.70

Thermal conductivity [W/m.K]: 20.0 Electric resistivity [Ohm mm2/m]: 0.65 Specific heat capacity[J/g.K]: 0.46

Disclaimer: the information and data presented herein are typical values for reference and are not intended as warranties to readers.