The chemical composition range of 65Mn steel is shown in the following table:

| Element | Content Range (%) |

| Carbon (C) | 0.62 – 0.70 |

| Silicon (Si) | 0.17 – 0.37 |

| Manganese (Mn) | 0.90 – 1.20 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.035 |

| Chromium (Cr) | ≤ 0.25 |

| Nickel (Ni) | ≤ 0.35 |

| Copper (Cu) | ≤ 0.25 |

The applications of 65Mn steel are as follows:

- Spring Manufacturing: It is widely used in the production of various springs, such as small-sized flat springs, round springs, cushion springs, spring coils, spring rings, valve springs, clutch spring plates, brake springs, and clockwork springs. The high carbon content and appropriate manganese addition endow the steel with excellent elasticity and hardness, enabling it to withstand repeated deformations and provide reliable elastic force.

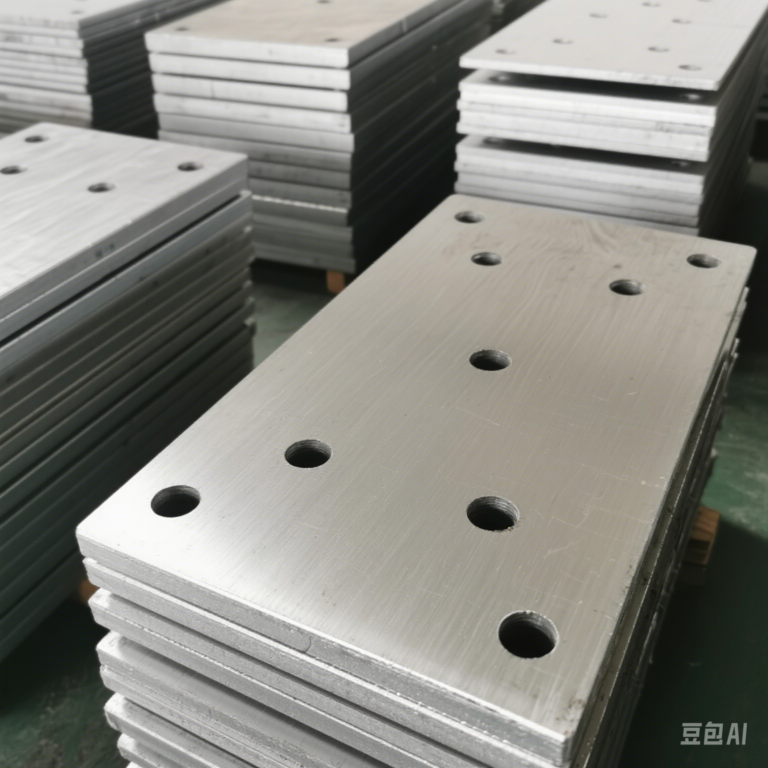

- Mechanical Parts Production: Commonly used to manufacture mechanical parts that require high strength and wear resistance, like gears, shafts, shaft sleeves, and crankshafts. These parts can operate stably under heavy loads and high friction conditions, ensuring the normal operation of mechanical equipment.

- Tool Making: Can be used to make some simple tools with certain hardness requirements. Although its hardness is not as high as that of some special tool steels, it can still meet the needs of processing some less hard materials in certain occasions due to its relatively good strength and wear resistance.

- Mold Industry: 65-Mn steel is suitable for manufacturing various molds, such as stamping dies, drawing dies, etc. It can improve the wear resistance and service life of molds, and ensure the dimensional accuracy and surface quality of molded parts.