Five Main Benefits of Customizing and Roughing for forging dies

1. Shape customization for material waste reduction

Customizing forging dies allows us to shape the die according to specific requirements. This means that the material is precisely formed into the desired shape, minimizing material waste. For example, in the production of complex – shaped components, the die can be designed to use only the necessary amount of material, reducing the cost of raw materials. This not only saves resources but also cuts down on waste disposal costs.

2. Cost – effective by reducing expensive processing

By customizing and roughing the forging die, we can significantly reduce the amount of expensive processing required. The roughing process helps to pre-shape the die, eliminating the need for extensive machining operations. This reduces the overall cost of processing, as less time and labor are spent on cutting and shaping the die. For instance, compared to traditional machining methods, the roughing process can reduce the number of machining steps, thereby saving both time and money.

3. Minimizing material quality risks

When customers opt for customized forging dies, they only need to perform precision milling on the die. This reduces the risk of material quality issues such as UT and hardness problems. Since the die is already pre-shaped through the roughing process, the material has already been tested and verified. This ensures that the die is free from internal defects, giving customers peace of mind and reducing the potential for quality – related problems.

4. Fast delivery within 25 – 40 days

The process of customizing and roughing for forging dies is highly efficient, enabling us to deliver within a short period of 25 – 40 days. This quick turnaround time is beneficial for customers who are under tight deadlines. It allows them to get their products into the market faster, improving their competitiveness. Whether it’s a large – scale project or a small – batch order, the fast delivery time ensures that the production process is not delayed.

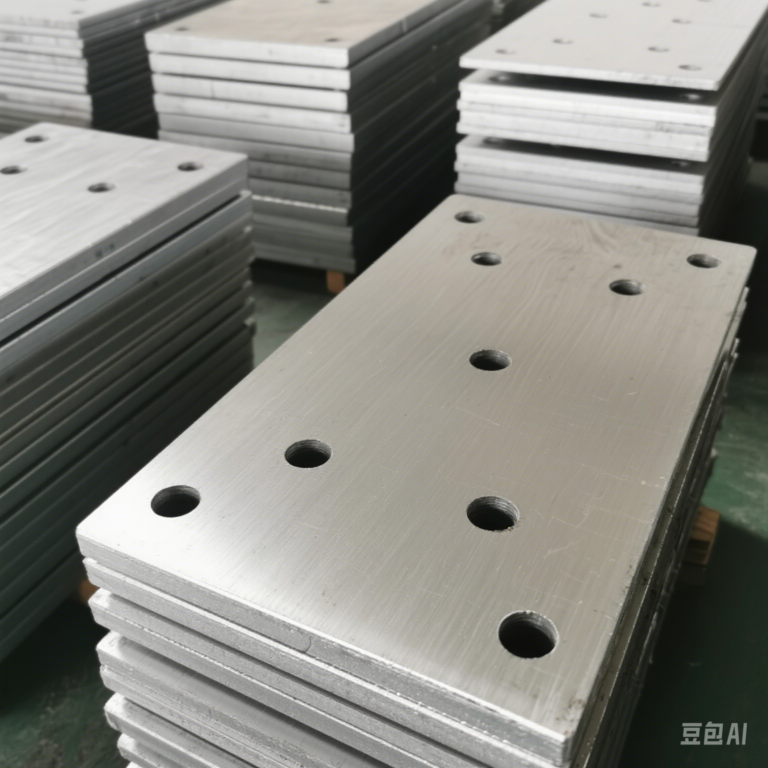

5. Ideal for semi – finished products of large – scale plastic and automotive molds

Custom forging dies are well – suited for the production of semi – finished products of large – scale plastic and automotive molds. The roughing process can create a pre-shaped die that is ready for further processing. This is especially useful for large – sized molds, where the initial rough shape can be formed quickly and efficiently. The semi – finished products can then be further processed to meet the specific requirements of the final product, ensuring high – quality and consistent results.

In conclusion, customizing and roughing for forging dies offer numerous benefits, from cost – savings and quality improvement to fast delivery and suitability for large – scale production. These advantages make it an attractive option for businesses in various industries.